Never lose sight of your quality

Our vision systems learn from the best in your company and pass on this knowledge to your newest employees. Our technology makes it simple for your employees to easily check every work step and make adjustments where necessary. This way, assembly is error-free – from start to finish, regardless of professional qualification. Ensuring that everything runs like clockwork.

Vision systems that learn

ivii vision systems are valuable because they know how things are supposed to look ideally. They detect the smallest deviation from the ideal state that they learned. A crack in a surface, an incomplete delivery, bread buns that turned out too small, an incorrectly assembled drivetrain and much more. This is how errors are detected and corrected. The system learns constantly using AI technologies such as deep learning and machine learning. You can easily teach the system new parts or procedures yourself.

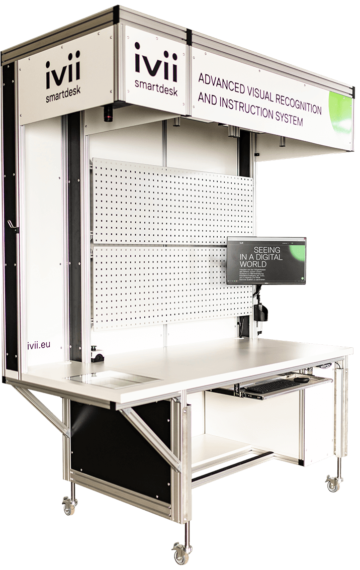

Our products in action

ivii vision systems ensure optimum processes in manufacturing and all along the production and supply chains, whether individual parts must be produced without error or incoming and outgoing goods checked.

Baked goods are rarely identical when they come out of the oven. ivii systems are able to make sure the volumes stay within the acceptable range to fulfill the quality requirements.

Digital vision lets you implement a zero-error strategy in your logistical processes. During ongoing operations, ivii systems work to validate existing master data and generate additional data, such as packaging type, which can be used to further optimize and automate the processes.

How can we help?

Would you like to partner with ivii, or find out more about our products?

We are here for you.